CVV-I/C AMS cables are used for electric signal transmission of control or monitoring circuits for 0.6/1kV

IEC 60502-1

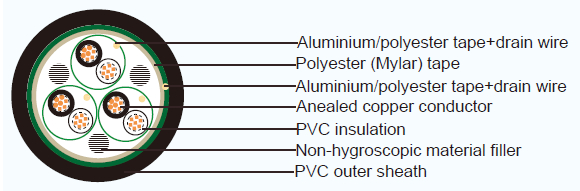

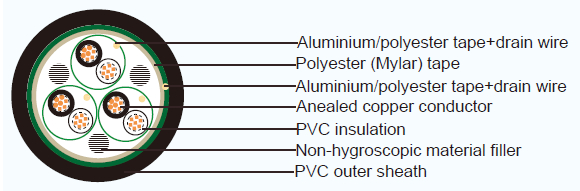

Conductor : Stranded annealed copper wires, Sizes: 1.5mm² up to 4.0 mm²

Insulation: Polyvinyl chloride (PVC)

Color : Black and white with marking numbers

Pairing/Ttaids : Two/hree insulated conductors uniformly twisted together

Individual Screen : Aluminium/polyester tape is applied over each pair metallic side down in contact with tinned copper drain wire.

Filler : Non-hygroscopic material(optional) Binding tape: Polyester (Mylar) tape (optional)

Overall Screen : Aluminium/polyester tape is applied over each pair metallic side down in contact with tinned copper drain wire.

Sheath : Polyvinyl chloride (PVC), Black color (other colors can be provided upn request)

Maximum conductor temperature 70°C

Circuit voltage not exceeding 600 volts

Test voltage : 3500 volts

| NO. OF PAIRS/TRIADS | CONDUCTOR | THICKNESS OF INSULATION | THICKNESS OF SHEATH | OVERALL DIAMETER | MAXIMUM CONDUCTOR RESISTANCE (AT 20°C) | CABLE WEIGHT | ||

|---|---|---|---|---|---|---|---|---|

| NOMINAL CROSS- SECTIONAL AREA | NO.& DIA. OF WIRES | DIAMETER | ||||||

| MM2 | MM | MM | MM | MM | MM | OHM/KM | KG/KM | |

| Pairs | ||||||||

| 2 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 16 | 12.34 | 280 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 17.5 | 7.56 | 350 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 21 | 4.7 | 460 | |

| 3 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 17 | 12.34 | 340 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 18.5 | 7.56 | 440 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 22 | 4.7 | 590 | |

| 4 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 18.5 | 12.34 | 420 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 20 | 7.56 | 540 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 24 | 4.7 | 740 | |

| 5 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 20 | 12.34 | 500 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 22 | 7.56 | 650 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 26.5 | 4.7 | 900 | |

| 6 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 21.5 | 12.34 | 580 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 24 | 7.56 | 770 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.9 | 29.5 | 4.7 | 1080 | |

| 7 | 1.5 | 7/0.53 | 2.59 | 0.8 | 1.8 | 21.5 | 12.34 | 630 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 24 | 7.56 | 830 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.9 | 29.5 | 4.7 | 1170 | |

| 8 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 24.5 | 12.34 | 720 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 27 | 7.56 | 960 | |

| 4 | 7/0.85 | 2.55 | 1 | 2 | 33 | 4.7 | 1370 | |

| 10 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 27.5 | 12.34 | 880 |

| 2.5 | 7.067 | 2.01 | 0.8 | 1.9 | 30.5 | 7.56 | 1190 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.2 | 38 | 4.7 | 1720 | |

| 12 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 28.5 | 12.34 | 1000 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 2 | 32 | 7.56 | 1380 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.2 | 39.5 | 4.7 | 1970 | |

| 15 | 1.5 | 7/0.53 | 1.59 | 0.8 | 2 | 32 | 12.34 | 1240 |

| 2.5 | 7.67 | 2.01 | 0.8 | 2.1 | 35.5 | 7.56 | 1700 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.4 | 44.5 | 4.7 | 2440 | |

| 20 | 1.5 | 7/0.53 | 1.59 | 0.8 | 2.1 | 36 | 12.34 | 1610 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 2.2 | 40 | 7.56 | 2210 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.5 | 50 | 4.7 | 3180 | |

| 30 | 1.5 | 7/0.53 | 1.59 | 0.8 | 2.3 | 42.5 | 12.34 | 2330 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 2.5 | 48 | 7.56 | 3240 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.9 | 59.5 | 4.7 | 4680 | |

| Triads | ||||||||

| 2 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 17.5 | 12.34 | 370 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 19.5 | 7.56 | 470 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 23.5 | 4.7 | 650 | |

| 3 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 19 | 12.34 | 470 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 20.5 | 7.56 | 600 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 25 | 4.7 | 830 | |

| 4 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 20.5 | 12.34 | 570 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 22.5 | 7.56 | 750 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 27.5 | 4.7 | 1050 | |

| 5 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 22.5 | 12.34 | 690 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 24.5 | 7.56 | 910 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.9 | 30.3 | 4.7 | 1300 | |

| 6 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 24.5 | 12.34 | 810 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 27 | 7.56 | 1080 | |

| 4 | 7/0.85 | 2.55 | 1 | 2 | 33.5 | 4.7 | 1550 | |

| 7 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 24.5 | 12.34 | 880 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 27 | 7.56 | 1180 | |

| 4 | 7/0.85 | 2.55 | 1 | 2 | 33.5 | 4.7 | 1690 | |

| 8 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 27.5 | 12.34 | 1010 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.9 | 30.5 | 7.56 | 1370 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.2 | 38 | 4.7 | 1990 | |

| 10 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.9 | 31.5 | 12.34 | 1250 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 2.1 | 35 | 7.56 | 1720 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.3 | 43.5 | 4.7 | 2470 | |

| 12 | 1.5 | 7/0.53 | 1.59 | 0.8 | 2 | 32.5 | 12.34 | 1450 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 2.1 | 36.5 | 7.56 | 1980 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.4 | 45.5 | 4.7 | 2870 | |

| 15 | 1.5 | 7/0.53 | 1.59 | 0.8 | 2.1 | 36.5 | 12.34 | 1770 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 2.2 | 40.5 | 7.56 | 2420 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.6 | 51 | 4.7 | 3550 | |

| 20 | 1.5 | 7/0.53 | 1.59 | 0.8 | 2.3 | 41 | 12.34 | 2320 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 2.4 | 46 | 7.56 | 3190 | |

| 4 | 7/0.85 | 2.55 | 1 | 2.8 | 57.5 | 4.7 | 4660 | |

| 30 | 1.5 | 7/0.53 | 1.59 | 0.8 | 2.5 | 49 | 12.34 | 3360 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 2.7 | 55 | 7.56 | 4650 | |

| 4 | 7/0.85 | 2.55 | 1 | 3.1 | 68.5 | 4.7 | 6790 | |